The specialist

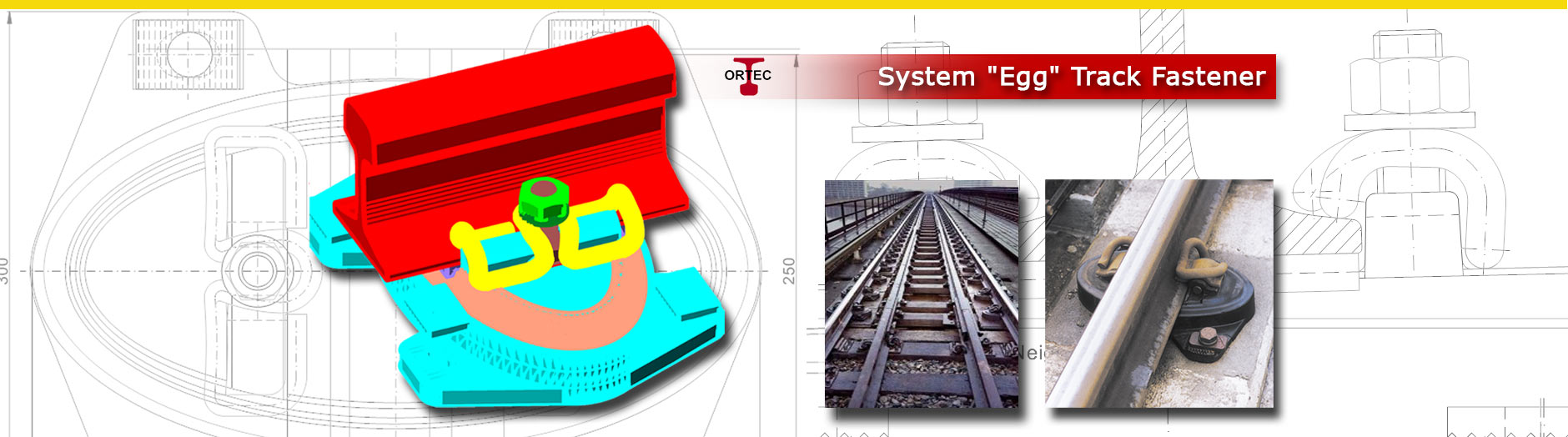

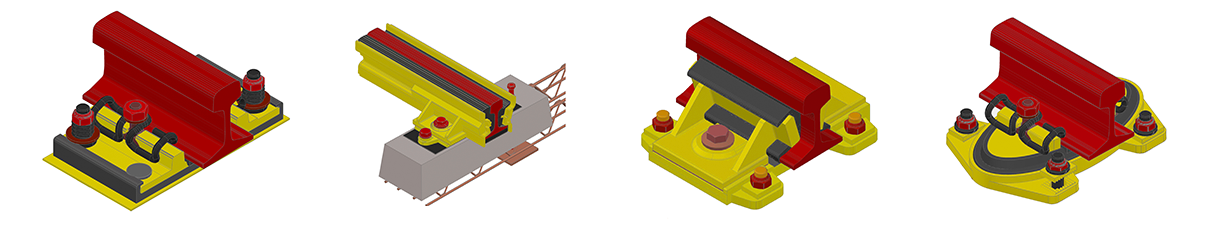

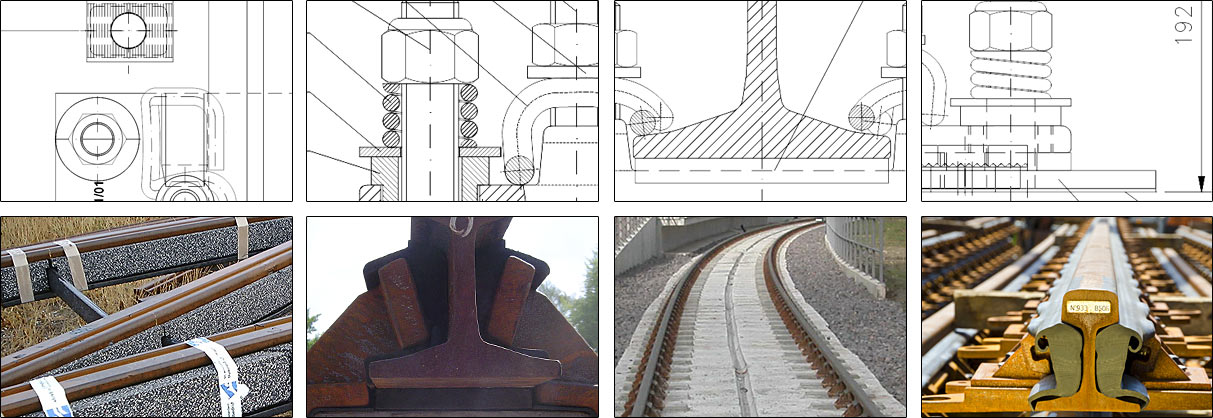

The "Egg" was designed to reduce structure-borne noise, which is the root cause of secondary airborne noise in buildings next to or above railway lines. The "Egg" consists of two metal parts – the ribbed base plate and the frame – which are connected together by a vulcanisation process. Spheroidal graphite iron was chosen as the most suitable material for all the metal components on account of its strength, durability, corrosion resistance and economic feasibility. An elastomer blend is used on account of its high resilience, long service life, and optimum ratio of static to dynamic rigidity. The rail is fastened on the ribbed base plate as specified by the customer, possibly with a Pandrol clip as in the example shown here. All other types of fastening can, of course, be considered. There are lugs on the outside of the frame with holes to take anchor bolts for fastenings on concrete. The ribbed base plate is supported by the vulcanised elastomer ring which is supported by the other side of the frame. This arrangement helps to distribute vertical forces into thrust and pressure components, resulting in the excellent acoustic efficacy of the "Egg". The design also ensures that the track gauge is retained. If subject to excessive load, the lowering of the ribbed base plate will be limited by the concrete.

This maintains the horizontal stability which is a considerable plus in terms of safety, especially on bends. The elastomer ring which connects the frame and ribbed base plate not only absorbs the vibrations but also offers an outstanding degree of electrical insulation. The vertical rigidity can be tailored to the requirements of the customer by adjusting the elastomer. The anchor bolts sit on the outside of the frame, allowing a frictional connection between the concrete and the seat of the rail. The anchor bolts are therefore only subject to tensile load. This is not the case with many other support systems.

Advantages at a glance:

- Reduction of shocks and vibrations

- Inbuilt protection from gauge widening caused by ageing

- Stray current insulation conforming to EN 50122-2

- Variable rail fastening

- Scope for adjusting system rigidity on ballasted and ballastless track sections

- Suitable for axle loads of up to 16 t

- Materials resistant to gritting and de-icing salt

- Materials selected with longevity of service in mind

- All materials 100% recyclable

List of references for Egg Track Fastener

| Location | Quantity | In operation since |

Vehicle | Axle load |

Railtyp |

| Boston | 3.600 | 1983 | U-Bahn | 14 t | AREA 115 |

| Washington, DC | 600 | 1986 | U-Bahn | 14 t | AREA 115 |

| Washington, DC | 2.100 | 1986 | U-Bahn | 14 t | AREA 115 |

| Washington, DC | 4.100 | 1990 | U-Bahn | 14 t | AREA 115 |

| Boston | 3.760 | 1994 | U-Bahn | 14 t | AREA 115 |

| Washington, DC | 10.100 | 1995 | U-Bahn | 14 t | AREA 115 |

| Los Angeles | 7.200 | 1998 | U-Bahn | 14 t | AREA 115 |

| Dallas | 900 | 2000 | U-Bahn | 14 t | AREA 115 |

| Total: 32.360 |